Francis Buehler AG

Bodenstrasse 23

6403 Küssnacht

Tel. +41 41 850 19 29

Fax +41 41 850 69 88

info@francisbuehler.ch

From producer to consumer - and back

The chronological tracking of relevant process steps allows producers, logistics providers or manufacturers to be assigned exactly to the respective product or production steps. In this way, errors can be avoided preventively or possible sources of error can be easily identified afterwards.

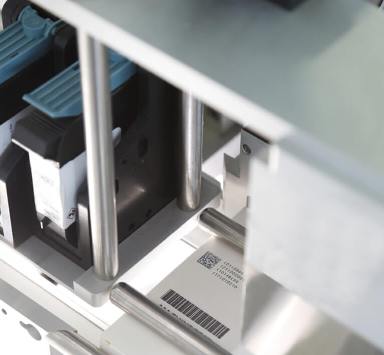

In addition to standard markings such as best before date (BBD), batch number or EAN codes, the use of variable QR codes, for example, allows the transparency and flow of information between producer, manufacturer, trade and the end consumer to be improved.

Depending on the control level, each individual product can be serialized and the applied label can be checked for presence and legibility immediately after printing. In this way, the product information of each individual article is recorded in a database and in the subsequent aggregation into larger units such as bundles, collective boxes and pallets. These units are in turn clearly marked and documented in a database.

What has been standard in the field of pharmaceutical production for years, we now offer in a modular version also for food production

- Choose the level of serialization and control that makes sense for your products.

- Cover the information needs of consumers

- Improve customer loyalty and brand trust